How to Use a Roll Container or Cage for Streamlined Order Fulfilment?

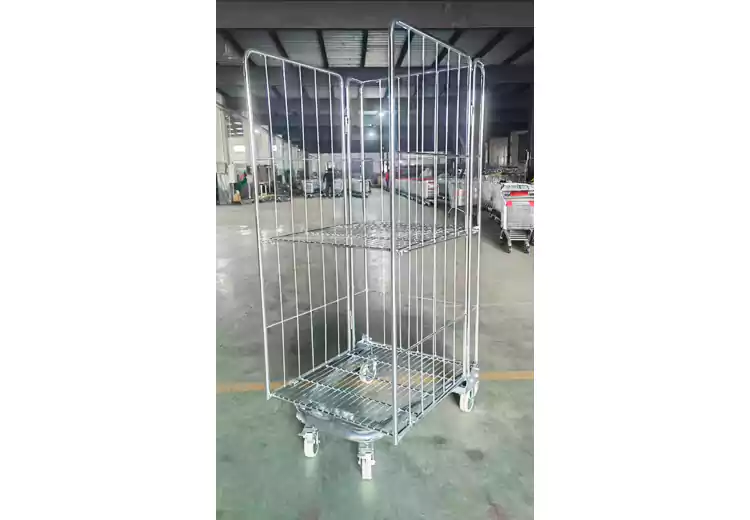

A roll container is made to hold a variety of goods and substances. With fortified walls to safeguard your products in any circumstance, these are some of the most sturdy containers on the market.

Industrial liquids including vehicle oil, solvents, water supplies, and cleaning products can be transported or stored in them. Additionally, they can securely contain heavy objects, such as raw resources and consumer goods.

Proper Order Fulfilment Can Help Save Money, Time and Effort!

The order fulfilment process, which is sometimes among the most expensive components of operating a warehouse, can be streamlined with the assistance of these containers. According to research, 50 to 65 % of warehouse labour costs are often incurred during order fulfilment and restocking. To have your products out from the door as soon as possible, understand how to complete orders using foldable roll containers.

Keeping Supplies and Raw Materials

The raw materials you use to manufacture your goods, such as wood, metal, plastic, cloth, and other production necessities, are ideal for storage in roll containers. They offer lots of room for bulky objects and shield them from the elements. Many containers have drop-down doors or open slots that make it simple to access the interior. When creating stuff, your workers may easily reach the supplies they require, allowing you to ship your goods out the door much more swiftly.

Transporting Supplies and Goods

Both raw materials and completed goods can be transported in a roll cage. They give you more room so you can ship larger quantities of your goods. To hasten loading and unloading, think about packing several containers inside a roll container. Instead of carrying hundreds of particular products manually, your employees can move substantial amounts of products with a lifting device.

Buy Roll Cages And Storage Containers To Store Your Goods Securely

Roll containers can assist you free up more room in the transport vehicle when it comes to transporting your items. After they have distributed the goods, your personnel can simply fold the container. They will be able to tell the difference between orders that have already been fulfilled and those that still need to be. They are spared the trouble of searching through empty bins for deliveries.

Inventory Management

These containers can also be used to arrange items on shelves. They are long lasting enough to safeguard your materials and goods throughout time. Your personnel will be able to quickly identify the goods if you store your goods in a roll cage with a drop-down opening. They can rapidly check goods for damage or put lost items back in the right spot.

When all these containers are empty, employees can also fold them, letting you know when it’s time to get more goods or materials. This will enable you to maintain an efficient stock inventory.

Your employees won’t have to access each container or go through empty boxes while searching the facility if something goes missing.

Utilizing Space

Operating a warehouse might make finding space challenging. Every year, the cost of hiring a facility increases. You may give your squad more area to walk around by using foldable containers to create as much space as you can from the loading dock. Your employees’ ability to do their duties will be hampered by clutter.

If they are lying down, they can trip and fall into a container or tumble over a box. Additionally, these containers will block their line of vision. To maintain the area as neatly as possible, encourage your employees to fold and stack empty containers as they move.

Less Waste

Boxes have to be disassembled, which can take a lot of time. The packing supplies, such as cling film and peanuts, must also be disposed of by your crew. The use of reusable containers is therefore recommended. As soon as an order is finished, your team may swiftly return these containers to circulation. At the end of the day, you won’t be complaining about buying more materials or reusing your resources.